Visibility

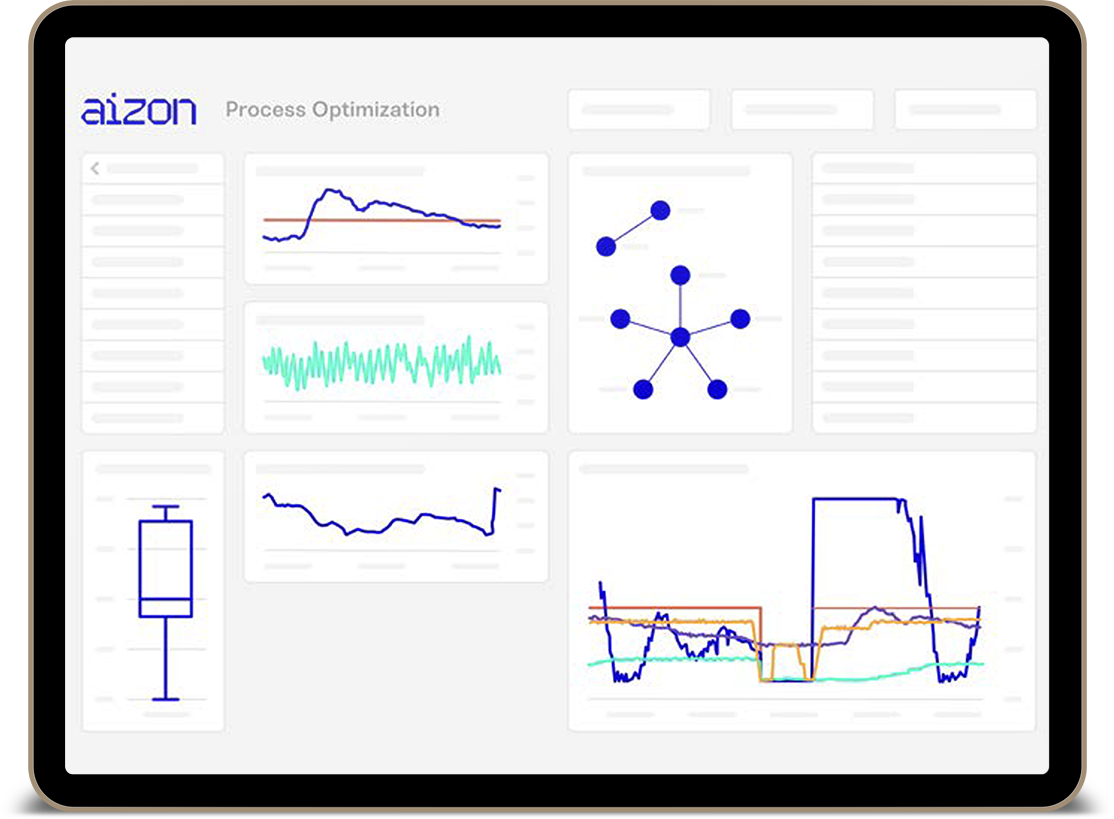

Access contextualized, unified data across all your teams in real-time

Confidence

Predict outcomes and eliminate the guesswork in process improvements

Resiliency

Protect your processes from excursions and deviations

Compliance

Automatically manage all your data in a GMP-compliant platform